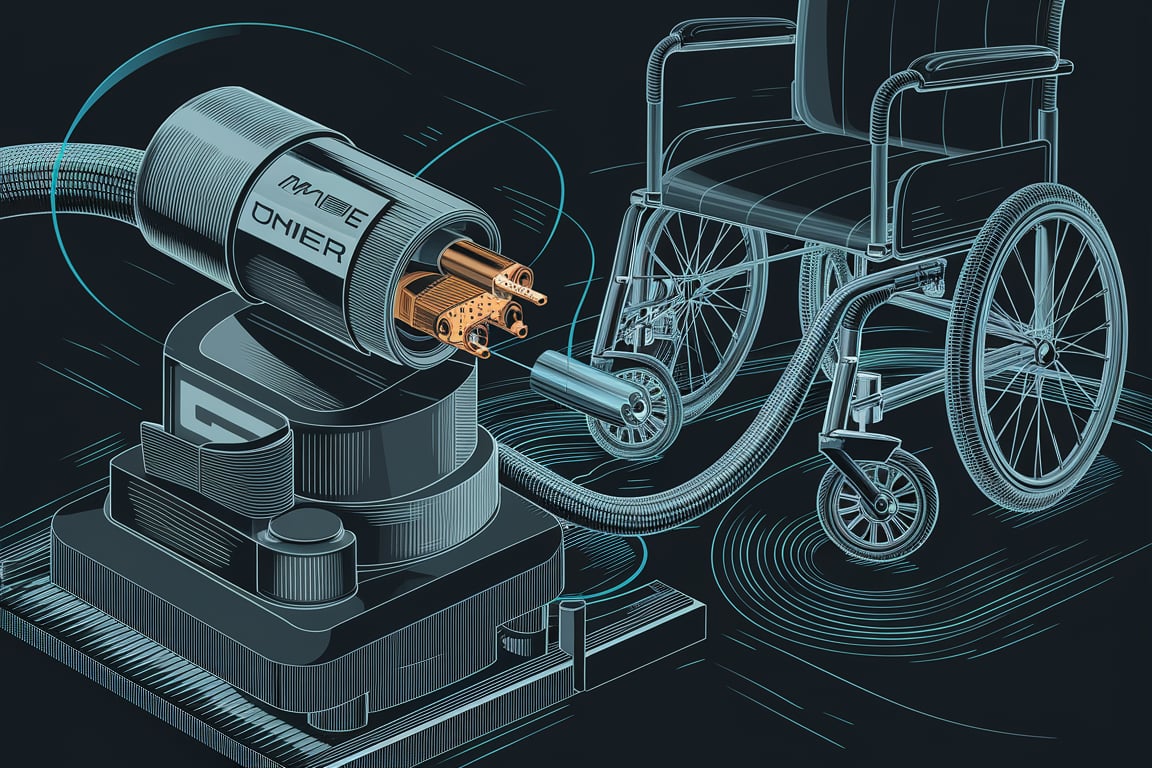

The mobility and efficiency of an electric wheelchair rely heavily on the components that power and control it. Among these crucial components is the connector cable for the Unite wheelchair motor. This cable plays a significant role in ensuring seamless power transmission and communication between the motor, battery, and control system. Understanding the features, specifications, types, and maintenance of these cables can enhance the longevity and performance of a wheelchair.

Understanding Unite Wheelchair Motors

Unite wheelchair motors are widely recognized for their efficiency, reliability, and adaptability in various mobility applications. These motors are typically used in power wheelchairs and electric mobility scooters to provide smooth movement and efficient power usage. However, to function optimally, they require a well-designed and robust connector cable that can handle electrical demands while maintaining durability under continuous use.

Importance of Connector Cables

The connector cable is essential for:

- Power transmission: Ensuring uninterrupted energy flow from the battery to the motor.

- Signal communication: Enabling data exchange between the control system and the motor.

- Safety and efficiency: Reducing energy loss and preventing electrical faults that could compromise user safety.

- Customization and adaptability: Allowing for modular connections, upgrades, and replacements when necessary.

Types of Connector Cables for Unite Wheelchair Motors

Several types of connector cables are used in wheelchair motors, each designed for specific functions and requirements. Below are the main types:

1. Power Cables

Power cables carry electricity from the battery to the motor. These cables must be:

- Thick enough to handle high currents without overheating.

- Insulated to prevent electrical hazards.

- Durable to withstand repeated bending and movement.

2. Signal Cables

Signal cables facilitate communication between the controller and the motor. These cables:

- Transmit data on speed, direction, and braking.

- Are typically thinner than power cables but require shielding to prevent interference.

- Use multi-pin connectors to accommodate complex signal transmission.

3. Charging Cables

Charging cables connect the wheelchair battery to a power source. These cables must:

- Match the battery’s voltage and current specifications.

- Have secure connectors to prevent accidental disconnections.

- Be resistant to wear and tear from frequent usage.

4. Universal Cables

Some connector cables are designed to work with multiple wheelchair models, allowing greater flexibility and compatibility. These cables are often modular and may include adapters.

Connector Types and Compatibility

The type of connector used in a cable is just as important as the cable itself. Common connector types include:

- Anderson Connectors: Known for their durability and high-current handling.

- XLR Connectors: Frequently used for battery charging applications.

- Molex Connectors: Popular for signal transmission due to their reliability.

- DC Barrel Connectors: Used in some lightweight motor connections.

- Custom Connectors: Designed specifically for proprietary wheelchair models.

Ensuring that the connector type matches the motor and controller specifications is crucial for optimal performance.

Factors to Consider When Choosing a Connector Cable

Selecting the right connector cable for a United wheelchair motor requires careful consideration of several factors:

1. Electrical Specifications

- Voltage and current ratings should match the motor’s power requirements.

- Ensure low resistance to minimize energy loss.

2. Cable Length

- The length should be sufficient to allow flexibility but not so long that it causes voltage drops.

- Consider coiled or retractable cables for better mobility management.

3. Durability and Flexibility

- Look for cables with reinforced insulation and strain relief to prevent damage from movement.

- Flexible cables reduce wear and increase lifespan.

4. Environmental Resistance

- Ensure the cable is resistant to moisture, dust, and temperature variations, especially for outdoor use.

- Shielded cables can reduce electromagnetic interference.

5. Ease of Installation and Maintenance

- Opt for plug-and-play connectors for easy replacement and troubleshooting.

- Modular cables allow for easier upgrades and compatibility with various motor models.

Maintenance and Troubleshooting of Connector Cables

Proper maintenance can significantly extend the lifespan of a connector cable and prevent unexpected failures. Here are key maintenance tips:

1. Regular Inspections

- Check for frayed wires, exposed insulation, and loose connectors.

- Inspect for overheating signs, such as melted plastic or discoloration.

2. Proper Storage

- Avoid excessive bending or tangling of cables.

- Store cables in a dry, cool place to prevent environmental damage.

3. Cleaning and Protection

- Use a dry cloth to remove dust and debris.

- Avoid exposure to water or corrosive substances.

4. Replacing Damaged Cables

- If a cable shows signs of wear or malfunction, replace it immediately to prevent damage to the motor or battery.

- Always use manufacturer-recommended replacements to ensure compatibility and safety.

Common Issues and Solutions

Despite their durability, connector cables may encounter issues over time. Below are some common problems and their solutions:

1. Loose Connection

- Problem: The motor loses power intermittently.

- Solution: Ensure connectors are firmly in place and clean any corrosion.

2. Overheating

- Problem: The cable becomes hot to the touch during operation.

- Solution: Check for undersized cables or excessive current draw.

3. Signal Interference

- Problem: The wheelchair responds erratically to controls.

- Solution: Use shielded cables and separate power and signal cables to minimize interference.

4. Cable Fraying or Damage

- Problem: The outer insulation is torn, exposing wires.

- Solution: Replace the cable immediately and use protective sheathing to prevent future damage.

Future Innovations in Connector Cables

The development of more advanced connector cables is continually improving wheelchair motor efficiency and user experience. Some future trends include:

- Wireless Power Transmission: Reducing dependency on physical cables.

- Smart Cables: Incorporating diagnostic sensors for real-time monitoring.

- Eco-Friendly Materials: Using recyclable and sustainable components.

- Enhanced Durability: Improved insulation and flexible materials for greater longevity.

Conclusion

The connector cable for a Unite wheelchair motor is a vital component that ensures smooth operation, efficiency, and safety. Choosing the right cable, maintaining it properly, and understanding potential issues can significantly enhance the wheelchair’s performance and reliability. As technology advances, wheelchair connector cables will continue to evolve, providing better connectivity, durability, and ease of use. Always ensure compatibility and quality when selecting a connector cable to guarantee the best experience for wheelchair users.